To help customers achieve their sustainability goals, Trinseo has developed a range of bio-based solutions as fossil-based alternatives. Trinseo strives to use second generation waste such as used kitchen oil and residue from the pulp industry that do not compete with the food chain and are consistent with a sustainable food future.

Thermoplastic Elastomers (TPE):

These materials can be developed to meet various requirements for hardness and customized to meet the needs of a specific application with performance properties that are comparable to those of traditional plastic material. Trinseo’s APICOLOR™ masterbatch solutions allow customers to apply color to their materials, with biodegradable options available in these additives.

Trinseo’s biobased TPE are used extensively in the fashion and footwear industry, consumer electronics, home appliances, personal care and the automotive sectors. Our material solutions power various applications, from shoe soles and synthetic textiles to phone cases and multiple automotive applications.

Styrenic Plastics

Trinseo offers its flagship STYRON™ Polystyrene, MAGNUM™ ABS, and TYRIL™ SAN resins with renewable content. These materials are derived from a combination of fossil-based and sustainable raw materials resulting in a bio-based composition up to 80 to 95 percent1.

STYRON™ CO2RE™ BIO Polystyrene, MAGNUM™ CO₂NET™ BIO, and TYRIL™ CO₂NET™ BIO provide a convenient, risk-free, and drop-in solution to customers who seek to further their sustainability efforts. The CO2RE™ designation indicates a measurable product carbon footprint (PCF) reduction when compared to our fossil-based products.

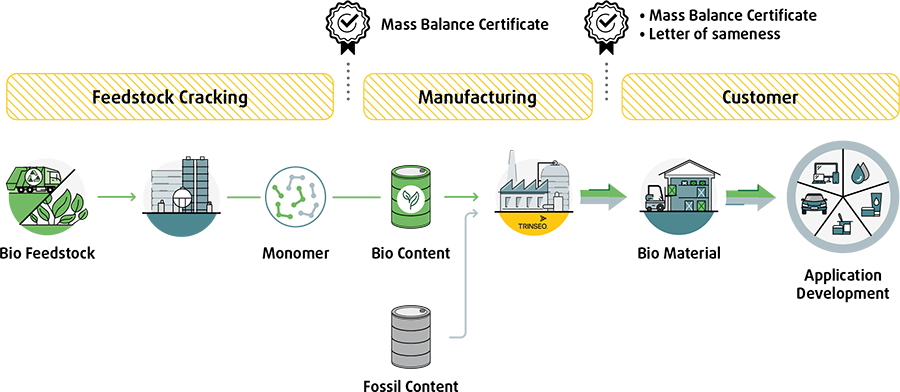

To produce STYRON™ CO2RE™ BIO Polystyrene, MAGNUM™ CO₂NET™ BIO, and TYRIL™ CO₂NET™ BIO, we rely on a process called feedstock cracking. During feedstock cracking, bio-feedstock is separated into its primary monomer building blocks. Only those monomers needed to produce the end material are filtered off for utilization during manufacturing. Material production is by conventional methods - all along adhering to ISCC Mass Balance processes to track sustainable content throughout the value chain.

ISCC Mass balance certification comes into play at three key junctures - once after the raw material refining process when the bio-feedstock is turned over for cracking, next after feedstock cracking, and again after the final material is manufactured, as it is delivered to the customer. Certificates of Mass Balance Compliance provide evidence of sustainable content for internal and external tracking purposes.

Currently to achieve a bio-based composition, Trinseo replaces the styrene and/or acrylonitrile with renewable material. Trinseo strives to use second generation waste such as used kitchen oil and residue from the pulp industry that do not compete with the food chain and are consistent with a sustainable food future. Because the renewable raw materials become identical in chemical composition to their fossil-based counterparts during feedstock cracking, segregation during manufacturing is unnecessary.

Trinseo’s BIO product portfolio offers identical performance properties and processability as fossil-based materials. Like their fossil-based counterparts, these materials can be used for a broad range of applications including automotive, appliances, building & construction, medical devices, and packaging.

In 2020, Trinseo launched its 2030 Sustainability Goals, an ambitious plan with 15 long-term goals grouped within five main categories: